1. According to whether the flow rate is adjustable, it can be divided into variable displacement pumps and quantitative pumps.

The output flow rate that can be adjusted according to needs is called a variable displacement pump,

while the flow rate that cannot be adjusted is called a fixed displacement pump.

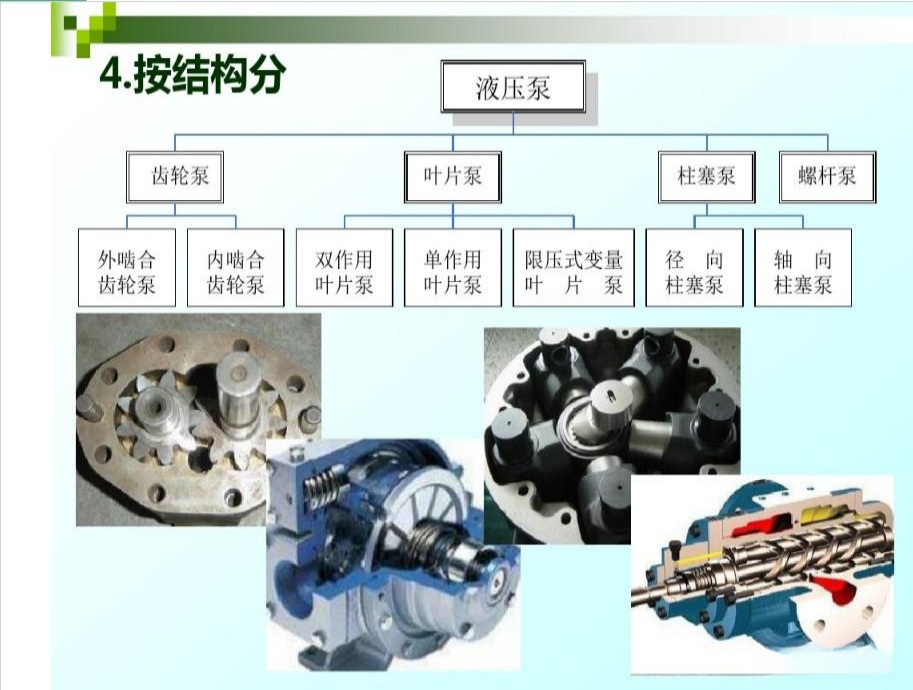

2. According to the commonly used pump structures in hydraulic systems, there are three types: gear pumps, vane pumps, and plunger pumps.

Gear pump: smaller in size, simpler in structure, less strict in oil cleanliness requirements, and cheaper in price;

But the pump shaft is subjected to unbalanced force, severe wear, and significant leakage.

Vane pump: divided into double acting vane pump and single acting vane pump.

The pump has uniform flow, stable operation, low noise, higher working pressure and Volumetric efficiency than gear pump, and more complex structure than gear pump.

Plunger pump: high Volumetric efficiency, small leakage, can work under high pressure, mostly used in high-power hydraulic systems;

But the structure is complex, with high requirements for materials and processing accuracy, expensive prices, and high requirements for oil cleanliness.

Generally, plunger pumps are only used when gear pumps and vane pumps cannot meet the requirements.

There are some other forms of hydraulic pumps, such as Screw pump, but the application is not as common as the above three.